An alternative would be to have the fan connected to the shroud and allow it to rotate with the blades. this would have benefits, A) allow an outboard bearing to support the outer tip (great) B) Increase rotational inertia substantially as hoops are better than solid disks {(1/2M*(Ri^2+Ro^2)) versus just (1/2*M*R^2)} (good), C) Minimize vortice shed at the tips as the blade tip conditions are more controlled/constant with no relative motion (probably not so important). However the detriments are the need for a small gap between the rotating shroud and stationary ducts on either side. This would also increase construction cost and complexity, things Steve doesn't want to hear....

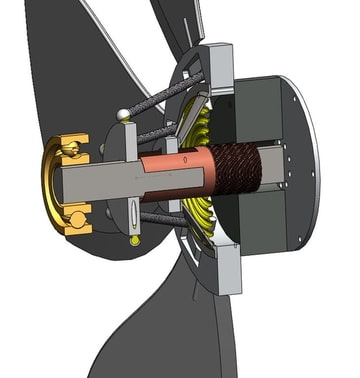

For the blades I tried to think of an cheap and easy way to form the blades in an aerodynamic manner but couldn't think of anything that did both. Seems it could be accomplished by a deep wood block clamshell CNC milled to a zero-lift foil shape, line it with mylar for nonstick, fiberglass it thinly, insert rod, and fill with Great stuff foam. but then you have additional milling. could be done by hand wiht a router and laminated/sanded but I suppose it would take forever. Even this method would probably lead to balance issues unless you were very meticulous with the fiber glass. could always balance later though. however this way the stiff arm is buried inside the foil and has no effect on the aero. Of course milling comes at the cost of about $80-100/hr plus markup on materials=expensive.

also to note is that an aerodynamically formed arm will offer little in terms of additional strength. for lateral loading of a shape like this, the elongation (streamlining) of the arm would be done along the neutral axis and thus not offer any additional strength to resist bending in the plane it would occur. You can google "bending beam stress distibution" to see what I'm talking about. It's a fundamental thought of mechanics of materials, bending stress is zero along the neutral axis. For a squarish beam it's (bh^3)/12 where h is the height of the beam. this simple relation is why I-beams have their shape and floor joists are tall, adding height gives strength at a cubic rate where width is linear. the flange at the outer edges bear the highest stress and that's why there there. the web connecting the two does little in terms of strength, just keeps the outer fibers in place. In this case it would be like making the web thicker and not changing the flanges.

The benefit it would add though is strength to the coupling between blade and axis and (as in the construction mentioned above) keep the blade from breaking free of the arm and hopelessly flopping about (the arm would twist inside the blade).